top of page

CATERHAM 420R BUILD

Jan 13, 2023

32. Radius Arm

The Radius Arms were very straightforward and per the manual, which indicates the dimpled surfaces of the arms face outwards, the chassis...

157 views0 comments

Jan 13, 2023

31. Dampers

The Dampers are reputed to be difficult to fit and the advice is to fit the upper bush first and then the lower one. However, when the...

275 views0 comments

Jan 13, 2023

30. Roll Bar

Before going any further with the rear suspension, the Roll Bar needed to be installed. The main bolts that support the Roll Bar would be...

134 views0 comments

Jan 13, 2023

29. DeDion

There were pre-drilled holes in the top of the DeDion tube indicating the riveting points for the brake line. However, these holes were...

257 views0 comments

Jan 13, 2023

28. Dry Sump Guard

Where the Bell Housing contacts the underside of the Engine and Dry Sump, there is a gap which exposes the Fly Wheel. Caterham supply a...

194 views0 comments

Jan 11, 2023

27. Handbrake

The handbrake microswitch was tested to establish (a) which of the two contacts should be used for correct operation and (b) to ensure...

118 views0 comments

Jan 11, 2023

26. Differential

Diff = Difficult! The engine hoist was setup to lift the differential unit using a pair of ratchet straps. It took some time to get to...

383 views0 comments

Jan 8, 2023

25. Propshaft

On delivery, the propshaft grease nipples were covered in paint. This was removed and the joints were verified as being pre-filled with...

158 views0 comments

Jan 8, 2023

24. Front Lights

The lights had been put on the back-burner until some feedback from Caterham had been received. When the first headlight was unpacked it...

514 views0 comments

Jan 8, 2023

23. Throttle Cable

The throttle cable runs from the top of the accelerator pedal, through and out of the pedal box, loops around the front of the engine and...

101 views0 comments

Jan 2, 2023

22. Steering Column

The Steering Column is split into two parts, upper and lower, both of which are fitted through the opening in the cockpit. The lower was...

169 views0 comments

Jan 2, 2023

21. Collector

The fitment of the Collector requires it to be slid into the end of the four Primaries. There is a risk of the Primaries being held too...

115 views0 comments

Jan 2, 2023

20. Air Box

Fitting the Air Box is straightforward except for the seal fits between the box and the bonnet. The issue is that the air intake is...

121 views0 comments

Jan 2, 2023

19. Catch Tank

Having previously drilled the necessary holes and fitted the catch tank bracket, the remaining task was to fit the oil hose from the top...

112 views0 comments

Jan 2, 2023

18. Oil Hoses

The hoses that connect the oil tank, dry sump and oil cooler are notorious. They use a specialised connector that have a draft angle on...

228 views0 comments

Dec 29, 2022

17. Oil Tank

Once the primaries were installed, the oil tank was fitted. This turned out to be a bit fiddly. the oil tank was dropped into position in...

159 views0 comments

Dec 29, 2022

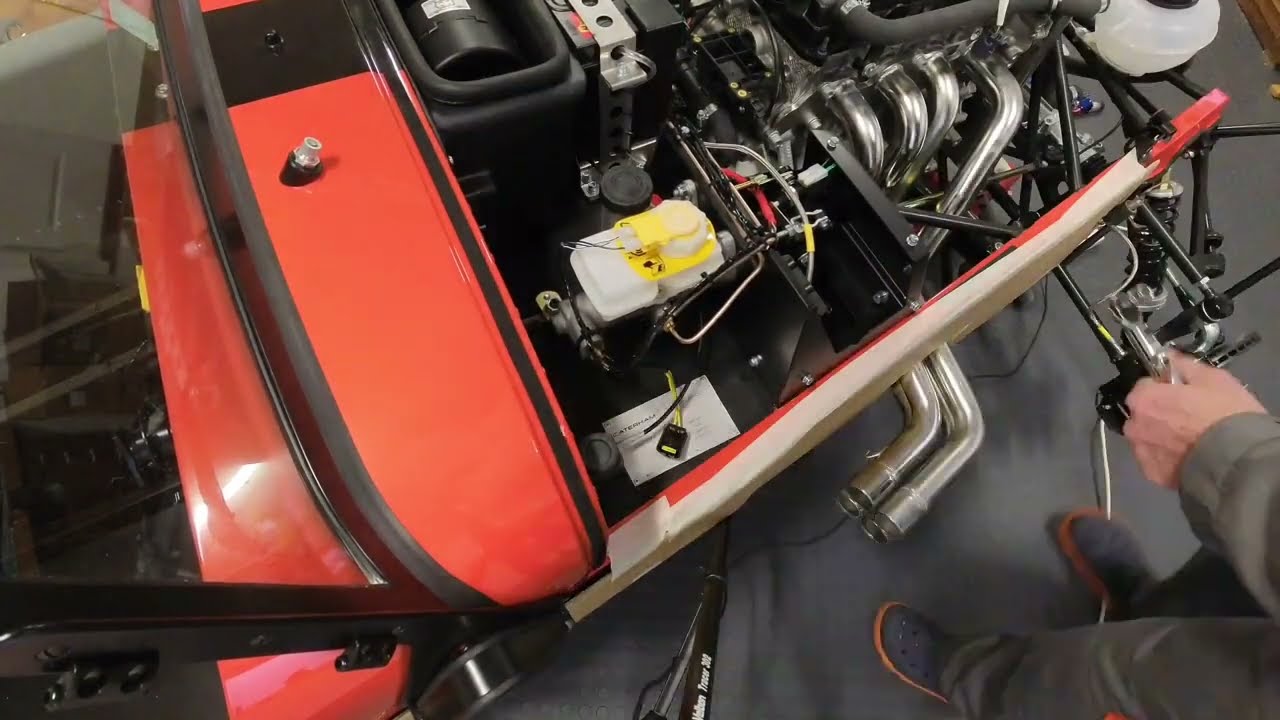

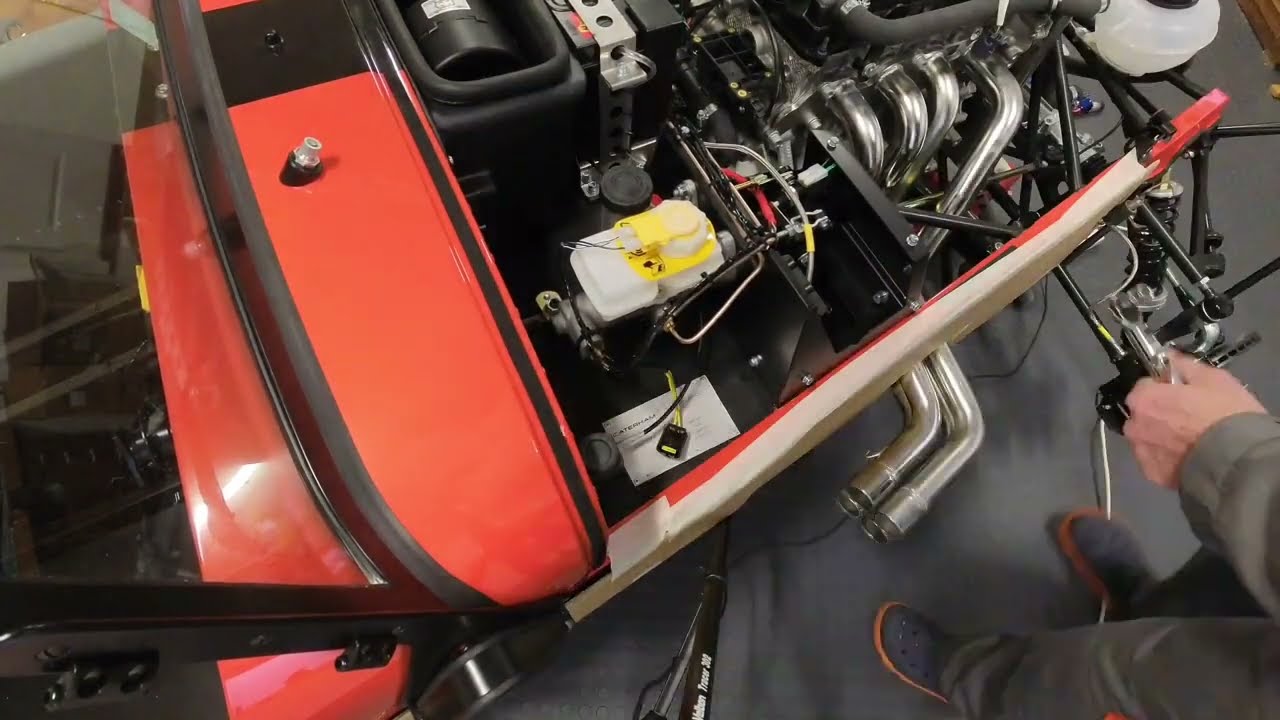

16. Primaries

As per my build plan, I knew that I could not install the oil tank (and therefore the oil plumbing) until the primaries were installed....

137 views0 comments

Dec 29, 2022

15. Plumbing

Having sorted out which hose goes where, I started the process of installing the plumbing by connecting the two lengths of hose to the...

248 views2 comments

Dec 28, 2022

14. Plumbing - preparation

There was quite a bewildering array of hoses that came with the kit and some of them require cutting and modification. Being nervous of...

222 views0 comments

Dec 28, 2022

13. Heater

Before starting the engine plumbing, I wanted to install the heater. This was relatively straightforward with the fan unit and radiator...

161 views0 comments

Dec 27, 2022

12. Drilling

There are two brackets that require fitting in the chassis - for the Oil Catch bottle and for the Expansion Tank. I wanted to get this...

137 views0 comments

Dec 27, 2022

11. Front Brakes

The front brakes are served by pipes fitted within the chassis. A fitting is required to connect the internal fixed pipes to the external...

232 views0 comments

Dec 27, 2022

10. Anti-Roll Bar

The two moulded plastic spheres at either end of the anti-roll bar (ARB) have to fit into the machined metal cups on the upper wishbones....

138 views0 comments

Dec 22, 2022

9. Uprights

I have an SV chassis which I believe is referred to in the manual as wide track. Therefore the first job is to fit the top hat spacer...

230 views3 comments

Dec 22, 2022

8. Dampers

This is where the trouble started! Both ends of the damper are fitted with bushes. At first, there are a bewildering array of different...

212 views0 comments

Dec 22, 2022

7. Steering Rack

The steering rack comes as a sub-assembly and held in position by a couple of clamps. The rack is put in place by feeding one end of it...

122 views0 comments

Dec 22, 2022

6. Upper Wishbones

When I offered up the wishbone to the fixing points it looked as though there was no way it was going to fit. I soon realised that the...

184 views0 comments

Dec 22, 2022

5. Lower Wishbones

To begin the process of installing the front suspension I first dressed the suspension apertures with IVA trim. The key decision was...

217 views0 comments

Dec 22, 2022

4. Engine Parts Refit

A simple task to refit the Alternator, Auxiliary Belt Tensioner and Starter Motor. However, there were some difficulties with torquing...

143 views0 comments

Dec 20, 2022

3. Engine In

I spent a good amount of time trying various methods of attaching the engine to the hoist in order to try to find a solution that would...

395 views0 comments

Dec 17, 2022

2. Bell Housing to Gearbox to Engine

The Engine, Bell Housing and Gearbox require assembly. Having taken advice from various blogs about using a method to remember which bolt...

274 views0 comments

Dec 17, 2022

1. Preparation

The first task was to prepare the chassis for the build. It arrived with the roof fitted and the bonnet in place. The rear wings, cycle...

345 views0 comments

bottom of page